Service

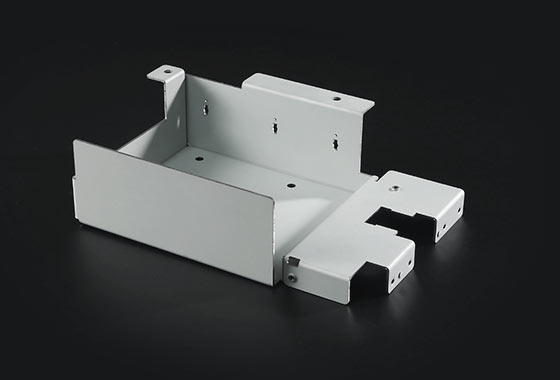

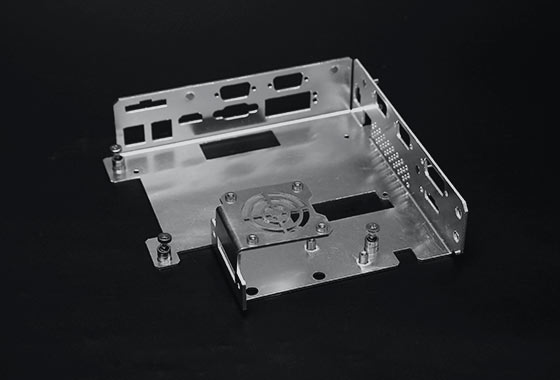

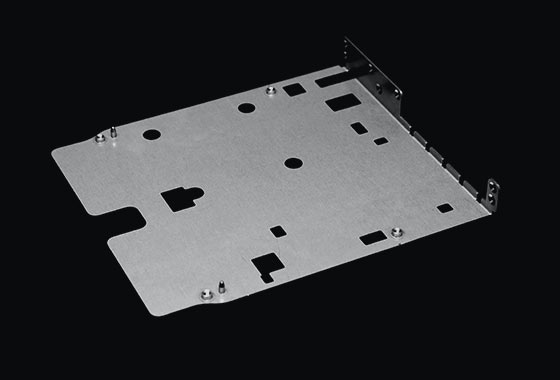

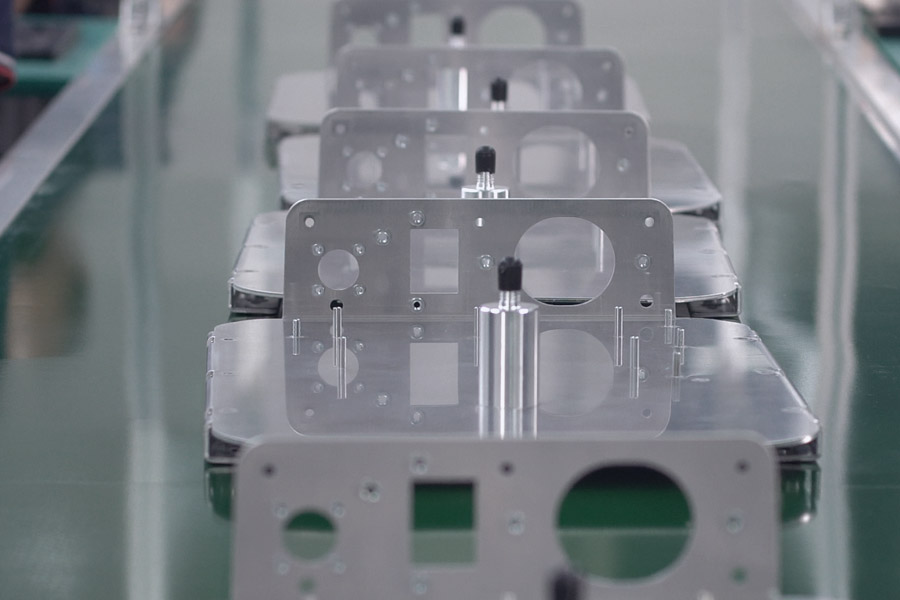

Sheet Metal Parts and Prototypes

For durable and lasting manufactured parts and prototypes using metals and alloys – GC-Prototype offers premier sheet metal fabrication services. Whether you’re looking for a one-off prototype, or thousands of identical parts we are ready to serve you. We offer extremely competitive pricing with no minimum order quantity. Achieve precise cuts, bends, and designs with sheet metal fabrication by GC-Prototype.

Materials available for machining

Many different metals and alloys can be used to create parts and prototypes in the sheet metal fabrication process. Depending on the design and application (industrial use, decorative applications, etc.), parts can be fabricated from the following metals

-

Aluminum alloy

-

brass

-

red copper

-

Stainless steel

-

Low-carbon steel

Metal plate

The basic thickness of the material for bending and stamping is 0.5 to 6 mm, and the thickness of the material for cutting is less than 10 mm. Sheet metal is cut, punched, punched, sheared, formed, bent, welded, rolled, riveted, drilled, tapped and machined crimped, etched, embossed, etc. Components can be plated, anodized, powdered Coating, painting, silk-screening or otherwise marking etc. to achieve the effect you want.

-

Stamping

-

Cut

-

Bend

-

Punching

-

Shear

-

Forming

Manufacturing With Sheet Metal

Sheet metal has an incredible number of applications for nearly every industry. Sheet metals can be sourced in nearly any thickness required, then formed into complex shapes or cut with incredible precision. Conductive capabilities, corrosion resistance, heat tolerance and more are all reasons to consider sheet metal in producing your next part or prototype.

Metals can be manipulated to accommodate your needs using many different manufacturing processes. The design, requirements, and materials will all factor in determining which sheet metal manufacturing process is best suited for your project. Some of the more-common processes include:

Bending the metals into shape

Hemming to reinforce metal edges

Laser cutting for precision designs

Punching designs directly from a sheet of metal

Seaming sheets of metal together creating a joint

Stamping images or designs into metals

Water-jet cutting, using jets of highly-pressurized water for a controlled erosion

No matter your requirements and demands we can produce your prototype, parts, and components using sheet metal both quickly and affordably.

Contact us today for a free sheet metal pressing quote. Our multi-lingual staff is standing by, ready to demonstrate our sheet metal pressing capabilities in English, Mandarin, French, Japanese and more!